地 址:南皮县泊东泊盐路南

免费电话:400-0317-986

电 话:0317-8309791

传 真:0317-8309792

邮 编: 062150

网 址:www.hedpump.com

E-mail:hedpump@yeah.net

Q Q:2854141514

一. ISW型卧式管道离心泵性能范围

流量范围:1.1-1450m3/h

扬程范围:7-150m

驱动方式:电机驱动

材质:铸铁、201、304、316、316L

密封方式:机械密封

电机选配:普通电机、电机、变频电机

二. ISW型卧式管道离心泵产品概述

ISW型卧式离心泵根据IS型离心泵与立式泵的结构组合设计,并严格按照标准ISO2858和的管道离心泵标准JB/T53058-93进行设计制造的节能产品。ISW型卧式离心泵采用国内水力模型优化设计而成。同时根据使用温度、介质等不同在ISW型基础上派生出热水泵、高温泵、化工泵、油泵等,是目前标准定型推广产品。

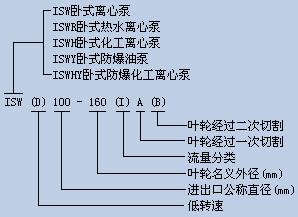

三. 型号表示意义

|

型号 |

流量 |

扬程 |

电机功率 |

转速 |

电压 |

效率 |

汽蚀馀量 |

|

|

m3/h |

L/S |

|||||||

|

15-80 |

1.2 |

0.42 |

8 |

0.18 |

2800 |

220 |

34 |

2.5 |

|

20-110 |

2.5 |

0.69 |

15 |

0.37 |

200 |

220 |

34 |

2.5 |

|

20-160 |

2.5 |

0.69 |

32 |

0.75 |

2900 |

220/380 |

25 |

2.5 |

|

25-110 |

4 |

1.11 |

15 |

0.55 |

2900 |

220/380 |

42 |

2.5 |

|

25-125 |

4 |

1.11 |

20 |

0.75 |

2900 |

220/380 |

36 |

2.5 |

|

25-160 |

4 |

1.11 |

32 |

1.5 |

2900 |

380 |

32 |

2.5 |

|

25-160A |

3.5 |

0.97 |

28 |

1.1 |

2900 |

220/380 |

31 |

2.5 |

|

32-100 |

4.5 |

1.25 |

12.8 |

0.55 |

2900 |

220/380 |

44 |

2.0 |

|

32-125 |

5 |

1.39 |

20 |

0.75 |

2900 |

220/380 |

38 |

2.5 |

|

32-12 |

4.5 |

1.25 |

16 |

0.75 |

2900 |

220/380 |

37 |

2.5 |

|

32-160 |

4.5 |

1.25 |

32 |

1.5 |

2900 |

380 |

35 |

2.0 |

|

32-160A |

4 |

1.1 |

25 |

1.1 |

2900 |

380 |

34 |

2.0 |

|

32-200 |

4.5 |

1.25 |

50 |

3 |

2900 |

380 |

32 |

2.0 |

|

32-200A |

4 |

1.1 |

40 |

2.2 |

2900 |

380 |

31 |

2.0 |

|

40-100 |

6.3 |

1.75 |

12.5 |

0.55 |

2900 |

220/380 |

54 |

2.5 |

|

40-100A |

5.5 |

1.53 |

10 |

0.37 |

2900 |

220/380 |

52.6 |

2.5 |

|

40-125 |

6.3 |

1.75 |

20 |

1.1 |

2900 |

220/380 |

46 |

2.5 |

|

40-12 |

5.5 |

1.53 |

16 |

0.57 |

2900 |

220/380 |

44 |

2.5 |

|

40-160 |

6.3 |

1.75 |

32 |

2.2 |

2900 |

380 |

40 |

2.5 |

|

40-160A |

5.5 |

1.53 |

28 |

1.5 |

2900 |

380 |

38 |

2.5 |

|

40-200 |

6.3 |

1.75 |

50 |

4.0 |

2900 |

380 |

33 |

2.5 |

|

40-200A |

5.5 |

1.53 |

44 |

3.0 |

2900 |

380 |

31 |

2.5 |

|

40-250 |

6.3 |

1.75 |

80 |

7.5 |

2900 |

380 |

27.5 |

2.5 |

|

40-250A |

5.5 |

1.53 |

70 |

5.5 |

2900 |

380 |

26 |

2.5 |

|

40-100(I) |

12.5 |

3.47 |

12.5 |

1.1 |

2900 |

220/380 |

62 |

2.5 |

|

40-100(I)A |

11 |

3.05 |

10 |

0.75 |

2900 |

220/380 |

60 |

2.5 |

|

40-125(I) |

12.5 |

3.47 |

20 |

1.5 |

2900 |

380 |

58 |

2.5 |

|

40-125(I)A |

11 |

3.05 |

16 |

1.1 |

2900 |

380 |

56 |

2.5 |

|

40-160(I) |

12.5 |

3.47 |

32 |

3.0 |

2900 |

380 |

52 |

2.5 |

|

40-160(I)A |

11 |

305 |

28 |

2.2 |

2900 |

380 |

48 |

2.5 |

|

40-200(I) |

12.5 |

3.47 |

50 |

5.5 |

2900 |

380 |

46 |

2.5 |

|

40-200(I)A |

11 |

3.05 |

44 |

4.0 |

2900 |

380 |

43 |

2.5 |

|

40-250(I) |

12.5 |

3.47 |

80 |

11 |

2900 |

380 |

36 |

2.5 |

|

40-250(I)A |

11 |

3.05 |

70 |

7.5 |

2900 |

380 |

34 |

2.5 |

|

50-100 |

12.5 |

3.47 |

12.5 |

1.1 |

2900 |

220/380 |

62 |

2.5 |

|

50-100A |

11 |

3.05 |

10 |

0.75 |

2900 |

220/380 |

57 |

2.5 |

|

50-125 |

12.5 |

3.47 |

20 |

1.5 |

2900 |

380 |

58 |

2.5 |

|

50-12 |

11 |

3.05 |

16 |

1.1 |

2900 |

220/380 |

53 |

2.5 |

|

50-160 |

12.5 |

3.47 |

32 |

3.0 |

2900 |

380 |

52 |

2.5 |

|

50-160A |

11 |

3.05 |

28 |

2.2 |

2900 |

380 |

48 |

2.5 |

|

50-200 |

12.5 |

3.47 |

50 |

5.5 |

2900 |

380 |

46 |

2.5 |

|

50-200A |

11 |

3.05 |

44 |

4.0 |

2900 |

380 |

43 |

2.5 |

|

50-250 |

12.5 |

3.47 |

80 |

11 |

2900 |

380 |

36 |

2.5 |

|

50-250A |

11 |

3.05 |

70 |

7.5 |

2900 |

380 |

34 |

2.5 |

|

500-100(I) |

25 |

6.94 |

12.5 |

1.5 |

2900 |

380 |

69 |

3.0 |

|

500-100(I)A |

22 |

6.11 |

10 |

1.1 |

2900 |

380 |

68 |

3.0 |

|

500-125(I) |

25 |

6.94 |

20 |

2.2 |

2900 |

380 |

67 |

3.0 |

|

500-125(I)A |

22 |

6.11 |

16 |

2.2 |

2900 |

380 |

63 |

3.0 |

|

50-160(I) |

25 |

6.94 |

32 |

4 |

2900 |

380 |

63 |

3.0 |

|

50-160(I)A |

22 |

6.11 |

28 |

3 |

2900 |

380 |

59 |

3.0 |

|

50-160(I)B |

20 |

5.56 |

24 |

2.2 |

2900 |

380 |

61 |

3.0 |

|

50-200(I) |

25 |

6.94 |

50 |

7.5 |

2900 |

280 |

57 |

3.0 |

|

50-200(I)A |

22 |

6.11 |

44.2 |

5.5 |

2900 |

380 |

55 |

3.0 |

|

50-250(I) |

25 |

6.94 |

80 |

15 |

2900 |

380 |

50 |

3.0 |

|

50-250(I)A |

22 |

6.11 |

70 |

11 |

2900 |

380 |

47 |

3.0 |

|

50-315(I) |

25 |

6.94 |

125 |

30 |

2900 |

380 |

38 |

3.0 |

|

50-315(I)A |

22 |

6.11 |

113 |

22 |

2900 |

380 |

38 |

3.0 |

|

65-100 |

25 |

6.94 |

12.5 |

1.5 |

2900 |

390 |

69 |

2.0 |

|

65-100A |

20 |

5.6 |

8 |

1.1 |

2900 |

380 |

70 |

2.0 |

|

65-125 |

25 |

6.9 |

20 |

2.2 |

2900 |

380 |

69 |

2.0 |

|

65-12 |

20 |

5.6 |

16 |

1.5 |

2900 |

|

|

|

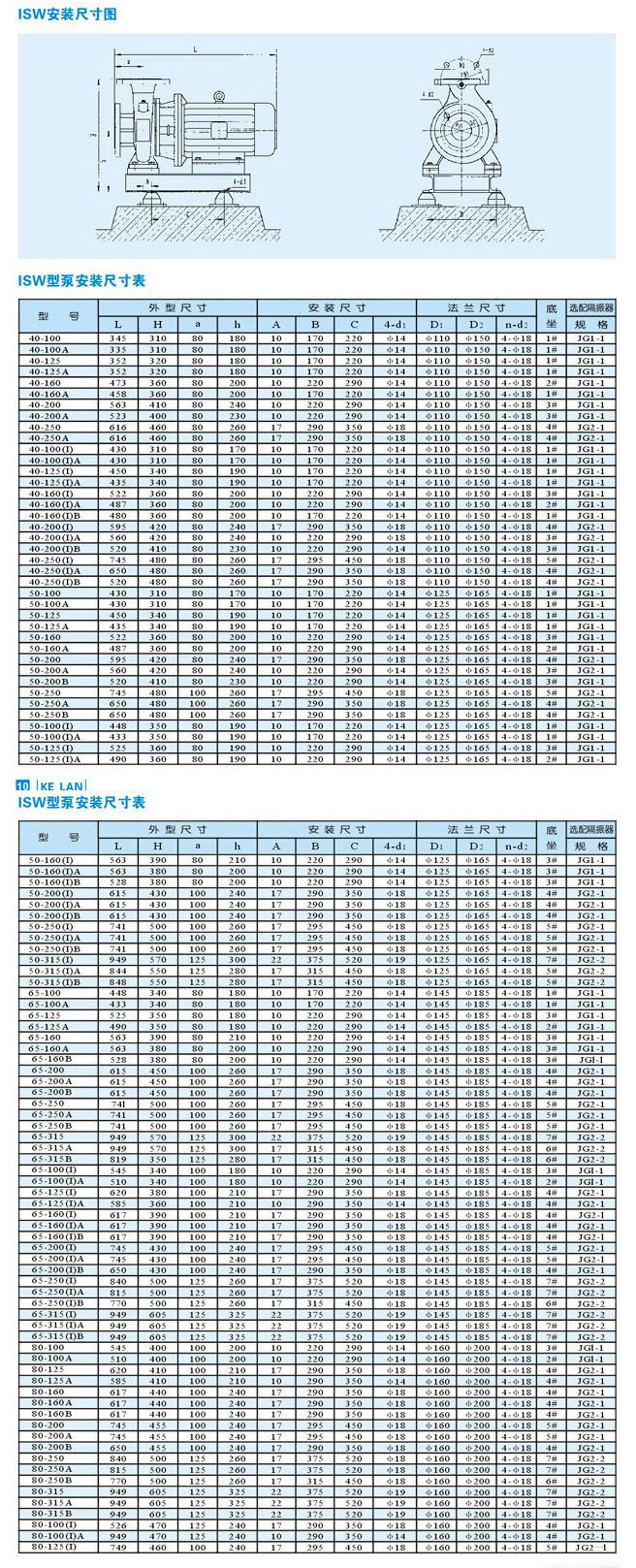

六.外形安装尺寸